repairing,sealing and bonding of oil,water,steam,acid,alkali pipeline flange surface under various high

temperature working condition.

Product description of BD757 wearing high temperature resistant metal pipeline sealing repair epoxy

ceramic compound putty:

It’s the high temperature repairing agent consist of modified high temperature resin and high temperature curing agent,

it’s made of filling polymerization from ceramic,metal,fiber and so on,super-heated steam resistant,various acid & alkali

corrosion resistant,oil resistant,good toughness,with a high bonding strength.The touching temperature can reach to 300 degree,

can work under 250 degree for a long time.Suitable for the repairing,sealing and bonding of oil,water,steam,acid,alkali pipeline flange

surface under various high temperature working condition.

How to use of our BD757 high temperature metal pipeline repair sealing ceramic putty epoxy compound:

1.Surface treatment: Do the coarsening treatment on the pending-repair or needing-bonding area,

then clean it by cleaning agent.

2.Configuration: According to the mass ratio A:B=5:1 or volume ratio A:B=4:1, make A and B two components mix uniformly,

and use it up within specified operation time limit.

3.Coating::Make the mixed-up material spread coating on the pending-repair area layer by layer,the first layer should be compacted,

make it infiltrate fully with the substrates.

4.Curing:Cure for 24 hours at the normal temperature,or cure for 2 hours at the temperature of 25 degree,

then heat it up to the temperature of 80 degree and keep this temperature for 2 hours,if the temperature is low in winter,

can heat it up or prolong the curing time to complete the curing.

Product performance index:

| product name | physical state | standard packaging |

Volume (cm3) |

operational time limit (25¡æ) |

curing time (25¡æ) |

|

757 high temperature sealing agent epoxy compound repair putty |

paste |

500g/set Two-component |

360 | 30min | 24h |

| color |

density (g/cm3) |

compressive strength (kg/cm2) GB1041-2008 |

shear strength (kg/cm2) GB7124-2008 |

bending strength (kg/cm2) GB1042-1999 |

hardness £¨Shore D£© ASTM-D-2556 |

dielectric strength £¨kv/mm£© |

working temperature £¨¡æ£© |

| gray | 1.4 | 867 | 120 | 150 | 86 | 16 |

-60¡«300 |

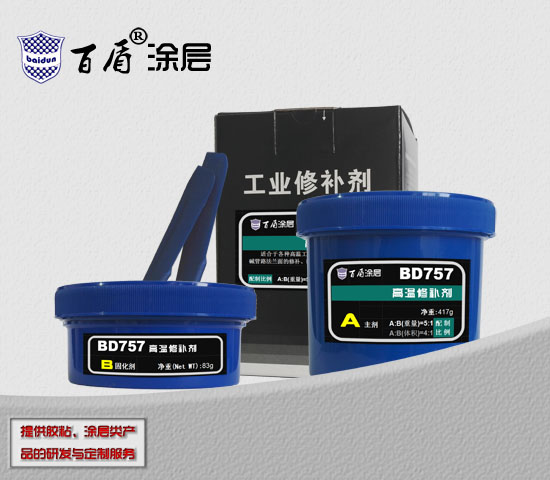

Product packaging photo of BD757 high temperature pipeline sealing agent epoxy ceramic compound repair putty: