BD114 high temperature anti chemical abrasion wearing resistant metal copper epoxy repair putty compound

used in repairing and protecting of the brass,bronze casting and process castings defects.

used in repairing and protecting of the brass,bronze casting and process castings defects.

Product description of BD114 high temperature wear abrasion resistant copper metal repair compound epoxy putty:

It’s the high performance polymerization metal materials compounded by various alloy material and modified

toughening heat resistant resin,suitable for the repairing and rebirth of the brass, bronze casting and process

castings defects.The color after repairing is basically the same as the substrates,with the very high strength

and excellent wear&corrosion resistance and aging resistant properties,can do various mechanical processing

together with substrates.

how to use of BD114 metal copper high temperature wearing resistant compound epoxy repair putty:

Surface treatment: Do the coarsening treatment on the pending-repair surface and clean it by cleaning agent.

2.Configuration: According to the mass ratio A:B=6:1 or volume ratio A:B=4:1, make A and B two components

mix uniformly,then use it up within specified operation time limit.

3.Coating: Make the mixed-up material spread coating on the pending-repair areas layer by layer,the first layer should be compacted,make it infiltrate fully with the substrates.

If the following working procedure needs machining,should keep out appropriate machining allowance

4.Curing: Curing for 8 hours at the temperature of 25-30 degree before doing machining,it can be put into using after curing for 24 hours ,if the temperature is low,should heat it up or prolong the curing time to promote the curing.

Performance index:

| product name | physical state | standard packaging |

volume (cm3) |

operational time limit (25¡æ) |

usable time (25¡æ) |

|

BD114 metal copper rebuilding repair compound epoxy coating |

paste |

250g/set Two-component |

163 | 45min | 24h |

| color |

density (g/cm3) |

compressive strength (kg/cm2) GB1041-2008 |

tensile strength (kg/cm2) GB6329-2008 |

shear strength (kg/cm2) GB7124-2008 |

bending strength (kg/cm2) GB1042-1999 |

hardness £¨Shore D£© ASTM-D-2556 |

working temperature £¨¡æ£© |

| brass | 152 | 922 | 367 | 273 | 512 | 87 |

-60¡«166 |

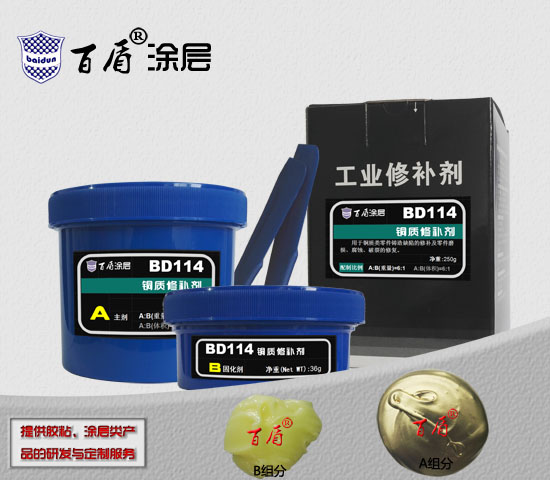

Product packaging actual picture of BD114 wearing high temperature metal copper repair putty epoxy compound coating: