pending-repair part layer by layer,the adhesive layer should be compacted,make it infiltrate fully with the substrates.Repair the surface to be smooth after the

coating is coated in the suitable size.This material can not do machining,should pay attention to controlling the coating thickness to avoid appearing interference phenomenon in the assembly.

5.Curing:It can be put into using after curing for 24 hours at the temperature of 25 degree,when the temperature is below 15 degree,the adhesive layer can't

be fully curing,should heat it up to the temperature of 80 degree and keep this temperature for 2 hours to promote the coating to be curing fully after the

coating initial curing(can use the iodine tungsten lamp to do irradiation heating with 40cm distance from the coating)

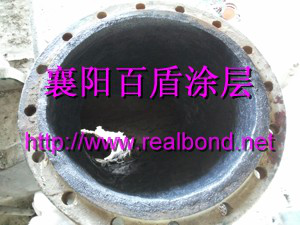

The effect picture after repairing: